5G-oriented "ERSA Solution"

Time:2022-03-04

Views:391

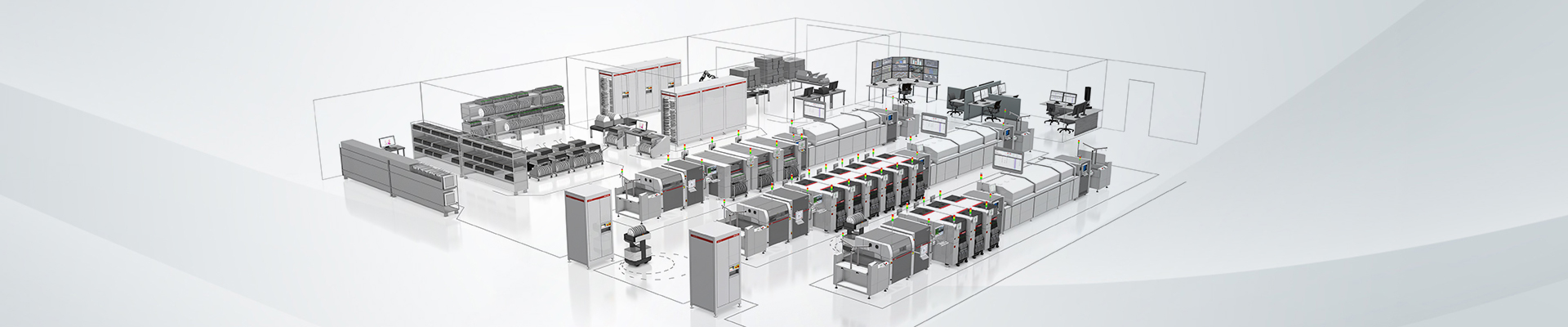

While 5G technology creates a fast and powerful network with a wider range, it also brings new challenges to the production of electronic products. In order to meet certain requirements of 5G product functions and options, adapt to the production capacity requirements of highly complex components and very large components, and comply with customer requirements for automation under the development trend of the industry, ERSA products customize complete solutions for 5G.

In general, ERSA‘s POWERFLOW series can handle all wave soldering tasks. The POWERFLOW ULTRA XXL has a working width of up to 610mm and a PCB length of up to 850mm, making it ideal for processing 5G server boards. The VERSAFLOW 3/66 XL can solder electronic components up to 3000 mm long. This model uses the largest servo operating system available and was specially developed for applications such as 5G antenna boards. The hybrid rework machine HR 600 XL was developed for the rework of large PCBs up to 625 x 625 mm. The innovative Infrared Matrix Heater™ with 16 kW of power and 25 times the zone heating capability ensures safe handling of rework of large and complex circuit boards.

Powerflow tunnel type full nitrogen-filled wave soldering: challenging ultra-difficult through-hole soldering with strength

1. Tunnel-type nitrogen filling throughout the process can analyze and monitor residual oxygen, and carry out closed-loop control of residual oxygen at the same time

2. Flux management and cleaning are carried out in the tunnel to reduce equipment maintenance time and improve production efficiency

3. The nozzles are sprayed with air before and after the flux spraying to prevent the nozzle from clogging when using rosin-type flux

4. Ultrasonic flux spraying reduces the amount of flux by 38% and achieves better flux atomization and penetration

5. Three preheating methods such as mid-wave infrared, short-wave infrared and hot air conduction can be freely combined

6. Use the top hot air preheating, which is especially suitable for the welding requirements of large heat capacity PCB, greatly improving the effect of tin penetration

7. The PCB can be divided into 10 areas to independently set the wave height to meet the welding requirements of different solder joints on the same PCB

8. The replacement of the soldering nozzle is very convenient, and it is convenient to switch the soldering nozzle when soldering different types of PCBs

9. Segmented track, claw conveying only in welding area, claw hook is free from flux contamination

10. Reinforced claw hook, L-shaped and V-shaped free combination, vibration-free, low thermal capacity, elastic, easy to replace, long life