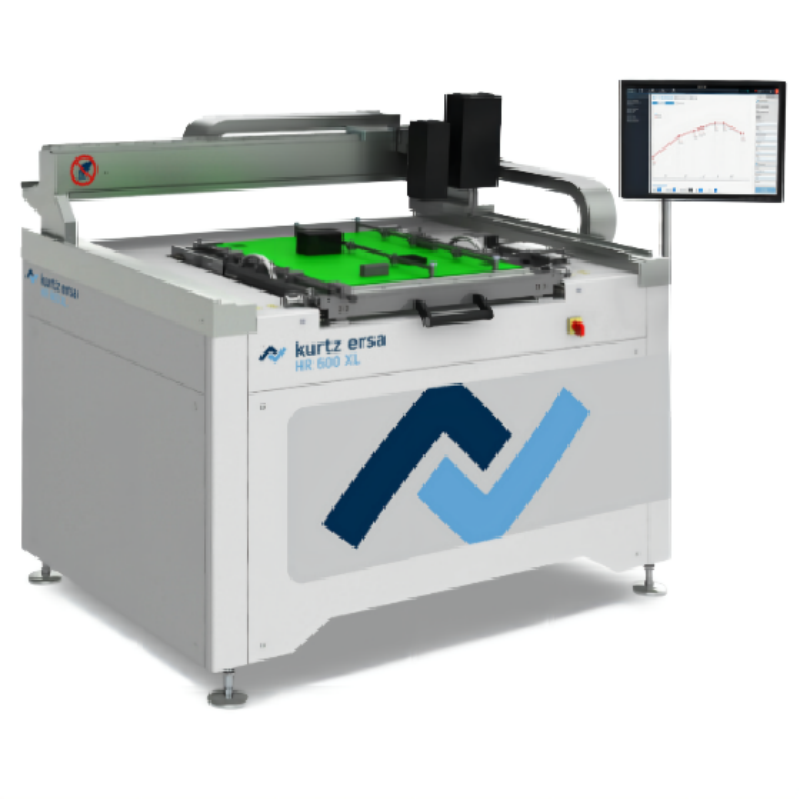

The HR600XL rework system newly developed and marketed by ERSA provides the best professional solution for solving the "five super" problems:

1. Fully automatic oversized circuit board repair system, no longer relying on people to ensure repair quality

2. 800W, 2000W or even 2800W top heating power to solve the problem of super large heat capacity

3. 80*80mm, 80*150mm or even 120*150mm top heaters to solve the problem of oversized components

4. 12mm, 15mm or even double suction nozzle extraction design to solve the problem of overweight components

5. Unique top hybrid heating technology, suitable for repairing any components in the 5G communication board

6. The 16,000W infrared heating platform at the bottom can handle circuit boards with a size of 625mm*625mm or more (up to 1.2m), and solve the problem of oversized circuit boards.

7. The heating module of the bottom 5*5=25 area is independently controlled, and the heating power is reasonably distributed to solve the problem of deformation of the super large circuit board

8. 1 infrared temperature measurement channel and 8 thermocouple temperature measurement channels to ensure the safety of oversized circuit board rework

9. 5 megapixel color true color mount camera to ensure high-quality placement of components during rework

10. The latest HRSOFT 2 rework software enables MES traceability of rework, perfectly matching Industry 4.0